Custom Web App Development Services for Optics Manufacturing: Transforming Your Business with Tailored Solutions

Here’s something we’ve noticed after working with dozens of manufacturers: the optics industry sits at this fascinating intersection of old-school precision engineering and cutting-edge digital innovation. And honestly? Most companies are still stuck somewhere in the middle, trying to make outdated systems work.

The numbers tell an interesting story.

The global optical lens market hit $19.05 billion in 2024. By 2032, it is expected to grow to $39.58 billion — that’s an 8.8% CAGR.

Meanwhile, the U.S. optical lens and instrument manufacturing industry alone has grown to $7.4 billion. There’s real opportunity here.

But here’s the catch: while demand skyrockets, many manufacturers are drowning in spreadsheets, juggling disconnected systems, and watching orders slip through the cracks because their technology can’t keep up. Sounds familiar?

Why Generic Software Just Doesn’t Cut It

Let’s be real about something. Your optics manufacturing operation isn’t like running a clothing store or a restaurant. You’re tracking lens coatings through multiple stages where even microscopic variations matter. You’re coordinating between manufacturing facilities and retail locations while managing prescription data where mistakes aren’t just inconvenient; they’re potentially dangerous.

Generic enterprise software? It was built for everyone, which means it wasn’t really built for anyone specific.

The data backs this up. Recent retail technology surveys found that 29% of businesses regret their software purchases because of poor usability. Another 36% struggle with training and onboarding. Now imagine dealing with those issues while trying to track substrate materials, coating processes, and quality metrics that off-the-shelf systems don’t even have fields for.

What Custom Optical Software Application Development Actually Does

Working with experienced optics manufacturing software developers isn’t about slapping together a few forms and calling it a day. It’s about building something that understands how your business actually operates.

Production Management That Actually Matches Your Workflow

Custom web applications track your specific process from raw material intake to final inspection. Real-time dashboards show order status, flag potential bottlenecks before they become fires to put out, and monitor the quality metrics that actually matter to your operation.

Here’s what’s interesting: over 6,500 firms globally now rely on optical simulation tools for prototyping and performance validation. That’s not a small number. And in 2023, more than 45% of R&D labs increased their budget allocation specifically for optics and photonics software. When nearly half the industry is putting more money into specialized software, they’re seeing something that works.

Quality Control Built Around Your Standards

In optics manufacturing, quality isn’t negotiable. A single defect can render an entire batch useless, and you’re often dealing with tolerances measured in microns.

Custom applications incorporate your exact testing protocols. They automatically flag products that don’t meet specifications. They maintain detailed compliance records. Most importantly? The system learns your standards and applies them consistently across shifts and facilities, something that’s nearly impossible to achieve with manual processes or generic software.

The global optical testing services market was valued at $1.2 billion in 2024. It’s projected to reach $2.5 billion by 2033. That explosive growth reflects how critical quality assurance has become. Custom software integrates these testing capabilities directly into your production workflow rather than treating them as separate operations that slow everything down.

Inventory Intelligence That Prevents Both Stockouts and Overstock

Managing inventory in this industry requires balancing numerous SKUs, tracking materials with specific shelf lives, and coordinating between manufacturing and retail operations. It’s complicated.

Custom software gives you visibility across your entire supply chain. It predicts demand based on historical data and market trends. It automates reordering to prevent stockouts without tying up capital in excess inventory sitting in warehouses.

Bridging the Gap: Manufacturing Meets Retail

Your manufacturing excellence doesn’t matter much if retail operations can’t effectively serve customers. And this is where integrated optical software for retail stores becomes genuinely valuable.

The global optical retail market sits at $279.24 billion with forecasted growth of 7.5% between 2022 and 2030. In the U.S. alone, the optical industry achieved a total market value of $68.3 billion in 2024, up 2.7% from 2023.

What Makes Optical Retail Software Different

Unlike mainstream retail, optical stores must manage highly technical data. Lens types. Frame measurements. Prescription specifications. Coating options. They need inventory management that tracks both fashion items (those plano sunglasses) and medical products (prescription eyewear). They require appointment scheduling integrated with customer records. They process two completely different types of transactions- prescriptions and non-prescription sales.

The optical software market was valued at $896.64 million in 2023 and is expected to reach $1,531.66 million by 2030, a CAGR of 6.13%.

This growth reflects increasing digitalization of healthcare delivery and demand for efficient, integrated, patient-centered solutions.

Custom web applications connect your manufacturing backend directly to retail frontends. When a customer orders custom lenses at a retail location, that order feeds directly into your production schedule. Your retail staff can see real-time production status and give customers accurate delivery estimates. Inventory levels update automatically as products move from factory to store.

No more phone tag. No more emails asking “where’s order #4521?” No more manual data entry creating errors. Your retail locations become extensions of your manufacturing operation rather than separate entities struggling to stay synchronized.

The Technology That’s Actually Making a Difference

Artificial Intelligence and Machine Learning

As of 2024, nearly 19% of optical software providers have embedded AI-based design optimization tools into their platforms. This isn’t just marketing fluff. The technology helps engineers reduce simulation time by 30% and boost design efficiency by up to 40%.

In manufacturing contexts, AI predicts equipment maintenance needs before breakdowns occur. It optimizes production schedules based on order priorities. It identifies quality issues earlier in the process when they’re easier and cheaper to fix.

Computer Vision and Automated Inspection

Computer vision systems can automate quality inspections with superhuman consistency. They catch defects that human inspectors might miss while maintaining perfect repeatability. This is particularly valuable in high-volume production where manual inspection becomes a bottleneck and let’s be honest, incredibly tedious for your team.

Cloud Architecture and Mobile Accessibility

Around 25% of new optical software licenses sold in 2023 were cloud-based, enabling collaborative design and real-time simulation. Cloud architecture means your team can access critical information from anywhere.

Your production manager can check order status from home at 6 AM before heading to the facility. Your sales team can pull up real-time inventory during client meetings. Your quality control specialist can review inspection data on a tablet while walking the factory floor.

Mobile-responsive interfaces ensure your software works as well on a smartphone as on a desktop workstation. Because the reality is that people work from everywhere now.

API Integrations

Custom applications connect with the tools you already use: accounting systems, shipping providers, CRM platforms, e-commerce sites. These integrations eliminate duplicate data entry and ensure information flows seamlessly across your technology stack.

How Custom Development Actually Works

Building custom software might sound intimidating. It doesn’t have to be. Experienced optics manufacturing software developers follow a structured approach that minimizes risk and maximizes value.

Discovery and Requirements Analysis

Development starts with understanding your current processes, identifying pain points, and defining what success actually looks like. This phase is crucial because it ensures the final product solves your real problems rather than creating new ones.

Good developers will ask detailed questions about your workflows, quality standards, compliance requirements, and growth plans. They’ll want to understand not just what you do, but why you do it that way.

Design and Prototyping

You’ll see mockups and interact with early versions. You’ll provide feedback before significant development resources are committed. This iterative approach means the software evolves based on real user input rather than assumptions.

Prototypes help identify usability issues early when they’re easiest and least expensive to fix. It’s much better to discover that a workflow doesn’t make sense during prototyping than after everything’s been built.

Agile Development and Testing

Development happens in stages with regular check-ins. Modern development practices emphasize continuous testing throughout the process, catching issues early rather than discovering them at launch.

You’ll see working features incrementally rather than waiting months for a complete system. This approach reduces risk and lets you start seeing value sooner.

Launch and Ongoing Evolution

Here’s something important: launch isn’t the end. It’s the beginning of an ongoing relationship.

Custom software grows with your business. It adapts to new requirements. It incorporates user feedback over time. Unlike commercial software that updates on the vendor’s schedule, your custom solution evolves when you need it to.

Security and Compliance Aren’t Optional

Your software handles sensitive information. Customer prescriptions containing personal health data. Proprietary manufacturing processes. Financial information. Competitive intelligence.

Custom development allows security measures tailored to your specific risk profile and compliance requirements.

Need HIPAA compliance for prescription data? SOC 2 certification for enterprise clients? Specific data residency requirements for international operations? Custom applications can be architected with these needs as foundational elements rather than afterthoughts bolted on later.

FDA oversight governs optical medical devices, requiring compliance with product quality, premarket notification, and reporting. Custom software can help you manage these requirements systematically rather than scrambling to compile documentation when auditors come calling.

Making the Investment Decision: Is It Worth It?

Let’s talk money. Custom optical software application development represents a significant investment. The optical design software market is forecasted to grow from $518.06 million in 2024 to $911.58 million by 2033, a CAGR of 6.48%. That reflects strong industry demand for specialized solutions.

But is it right for your business specifically? Consider these questions:

Are manual processes consuming hours of staff time each week? Time that could be automated?

Do you struggle to get accurate, real-time visibility into operations across facilities? Are you making decisions based on yesterday’s data or last week’s?

Are growth plans limited by current system capabilities? Have you heard someone say “we can’t scale that process”?

Is your team constantly working around software limitations? Do phrases like “the system won’t let me do that” come up regularly?

Do you lose orders or customers because you can’t provide real-time information when they need it?

If you answered yes to any of these, custom development deserves serious consideration. The upfront investment typically pays for itself through increased efficiency, reduced errors, improved customer satisfaction, and the ability to scale operations without proportionally scaling headcount.

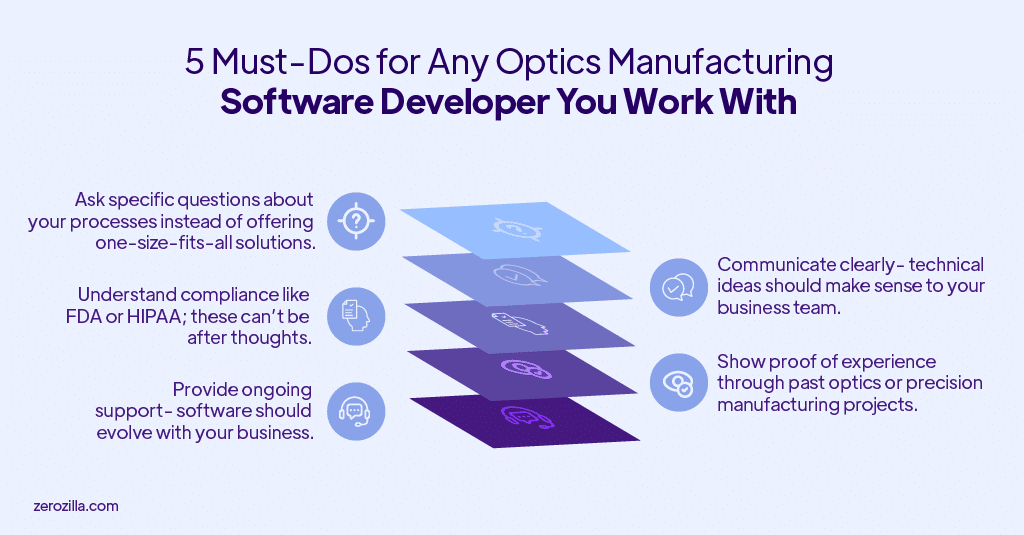

Finding the Right Development Partner

Not all software developers understand optics manufacturing. The complexities of lens fabrication, coating processes, prescription management, and quality control require domain knowledge that general web developers simply don’t possess.

The best development partners act as strategic advisors. They challenge assumptions. They suggest approaches you might not have considered. They stay engaged after launch to ensure your software delivers ongoing value.

The Challenges Custom Software Helps You Address

Rising Consumer Expectations

With a large proportion of adults regularly wearing eyewear, consumer expectations for service, personalization, and convenience have never been higher. Online retailers have shown what’s possible with virtual try-on features, free shipping, and seamless ordering experiences.

Traditional manufacturers and retailers must match these expectations or risk losing market share. Custom software that creates smooth, modern experiences helps you compete effectively.

Cost Pressures

Consumer purchasing behavior has shifted notably toward affordability. More buyers now prefer prescription eyewear costing less than $100 out of pocket, while fewer spend over $200 for prescription glasses.

This trend toward cost-effectiveness requires manufacturers to optimize operations and reduce waste, precisely what well-designed software enables. You can’t cut your way to profitability, but you can automate your way there.

Digital Transformation in Retail

From augmented reality try-on experiences to telehealth eye exams, digital tools are revolutionizing how consumers interact with optical retailers.

Manufacturers whose systems can’t integrate with these retail innovations risk being left behind. Custom software that bridges manufacturing and retail operations positions you to capitalize on these trends rather than scramble to catch up.

Supply Chain Complexity

Asia Pacific accounts for 41.05% of the global optical lens market in 2024, with manufacturing hubs concentrated in China, Japan, South Korea, Taiwan, and India. Supply chain coordination across time zones and continents is essential.

Cloud-based custom applications enable this coordination effectively. Your team in California can see what’s happening at your facility in Taiwan. Your supplier in Germany can check order status without sending an email.

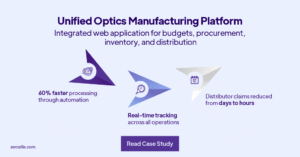

Case Study: Unified Web Platform for Optics Manufacturing Operations

Overview

A leading optics and photography equipment manufacturer was struggling with fragmented, Excel-based processes for managing budgets, procurement, inventory, rentals, and distributor claims. Zerozilla developed a fully integrated web application on React and Node.js that centralized these critical functions, replacing manual workflows with automated systems and providing real-time visibility across all operations.

Solution

- PO-NPS System — Centralized platform for procurement, budgets, purchase orders, material requisition forms, invoices, and camera inventory management

- Camera Rental Portal — End-to-end automation of rental requests, approvals, tracking, and returns with complete transparency

- Distributor Claims Portal — Streamlined submission and approval workflow for marketing and distribution claims

- Role-Based Access — Secure, customized access for internal teams and external distributors

Features

- Real-time budget tracking with automatic updates

- Interactive dashboards for monitoring KPIs and operational metrics

- Automated approval workflows reducing manual intervention

- Centralized data integration across all business functions

- Enhanced inventory visibility with real-time tracking

Impact

- 60% faster processing — Dramatically reduced time for POs, MRFs, and invoices

- Hours vs. days — Distributor claim cycles accelerated from days to hours

- Real-time visibility — Complete inventory tracking across all departments

- Reduced errors — Automation eliminated manual data entry mistakes

- Increased efficiency — Streamlined workflows boosted overall operational performance

Why It Matters

Manual, spreadsheet-based operations simply don’t scale. This transformation demonstrates how the right digital infrastructure can turn operational bottlenecks into competitive advantages. By unifying fragmented processes into a single, intelligent platform, the manufacturer gained the agility to make faster decisions, reduce costs, and scale operations without adding complexity. For manufacturing companies still relying on legacy processes, this case study proves that digital transformation delivers measurable ROI through efficiency, accuracy, and speed.

The Future Belongs to Companies That Adapt

The optics industry continues evolving. New materials. Advanced manufacturing techniques. Changing customer expectations. Off-the-shelf software will always lag behind these changes- updated on someone else’s timeline to serve the broadest possible market.

Custom web applications evolve on your timeline. They incorporate new capabilities exactly when your business needs them.

As the precision optics market grows from $29.0 billion in 2024 to a projected $92.9 billion by 2034 at a CAGR of 12.7%, manufacturers with agile, tailored technology solutions will capture disproportionate value.

This agility transforms software from a constraint into a competitive advantage. While your competitors struggle with rigid commercial software that doesn’t quite fit their needs, your custom solution adapts seamlessly to new requirements, market conditions, and opportunities.

Ready to Start the Conversation?

Whether you’re manufacturing precision lenses for medical devices, coordinating optical retail locations, or managing complex international supply chains, custom optical software application development offers a path forward that generic solutions simply cannot match.

The conversation starts with understanding your unique challenges and opportunities. From there, experienced optics manufacturing software developers can map out solutions that transform how your business operates, competes, and grows.

The question isn’t whether custom software can help your business; the market data and industry trends make that clear. The real question is whether you can afford to wait while competitors who embrace tailored technology solutions pull ahead.

The first step is simple. Reach out to Zerozilla, as we understand both software and your industry. As a digital and software development solutions company specializing in custom web applications for specialized industries, including optics manufacturing, our team combines deep technical expertise with industry knowledge to deliver solutions that drive measurable business results. Contact us to discuss how custom software can transform your optical manufacturing operations.